Controls: Thin films deposited onto optical surfaces used to increase transmission of the surface. AR coatings are matched to the requirements of each optic, ranging from the most common and cost-effective single-layer MgF2 to custom, multi-band designs specific to a single application

Related Terms: Witness sample (used to test performance), coating durability, adhesion, MIL-C-675C, MIL-F-48616, MIL-C-48497A, MIL-M-13508C

Specifications Must Contain: Wavelength band in linear units, Percent Reflectance or Transmission, Angle of Incidence (if other than normal incidence), and minimum coating aperture (if different than Clear Aperture).

Specifications May Include: Laser Damage Threshold in J/cm2 (include Pulse-width, wavelength, repetition rate, spot size), multiple wavelength bands, combinations of R and T specs, polarization requirements.

Optimax Preferred Specification: Average Reflectance, normal incidence

Reasons: Metrology is the most straightforward

Manufacturing Standards: MIL-C-675C, MIL-F-48616, MIL-C-48497C, MIL-M-13508C, MIL-C-14806A, ISO, OEOSC OPI.0110-9, OPI.9211-2, OPI.9211-2, OPI.9211-1

Find out more by downloading our technical note on Phase Distortion On Interferometric Measurements Of Thin Film Coated Optical Surfaces

Samples of Standard Coatings Available at Optimax:

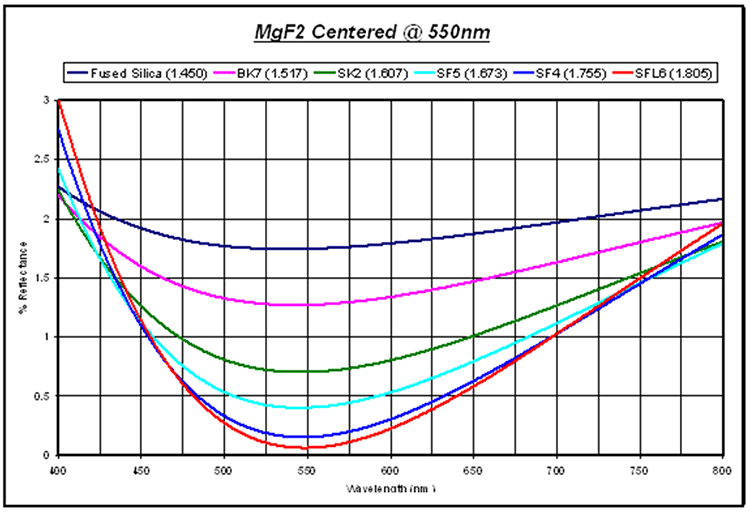

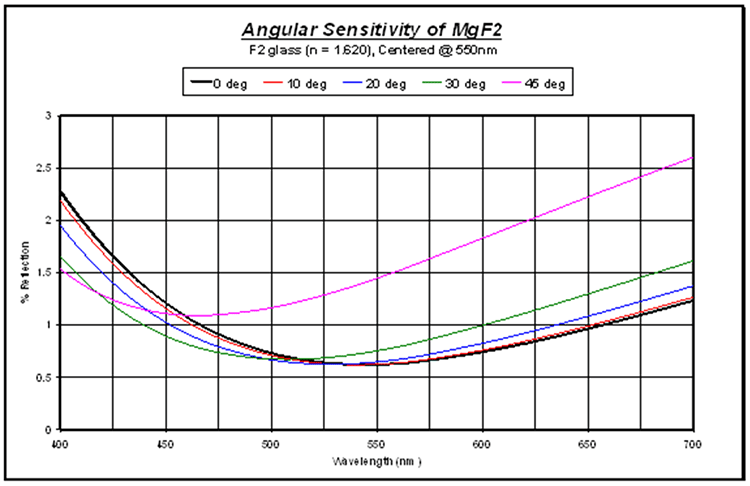

Single Layer (/4 thick) MgF2

- Most cost-effective option

- Same coating for all-optical glasses

- Performance varies with substrate index

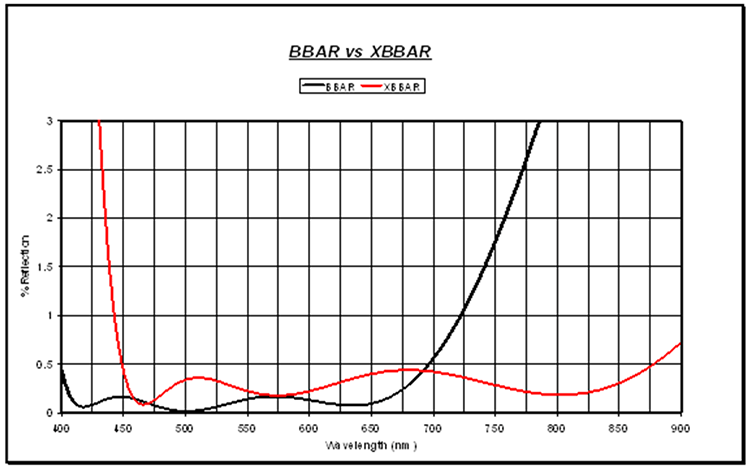

Broad Band Antireflectives

- BBAR optimized for 400-700nm

- Extended BBAR optimized for 450-900nm

- Ravg < 0.5%, Rmax < 1.0%, AOI: 0-30˚

- Better performance, higher cost

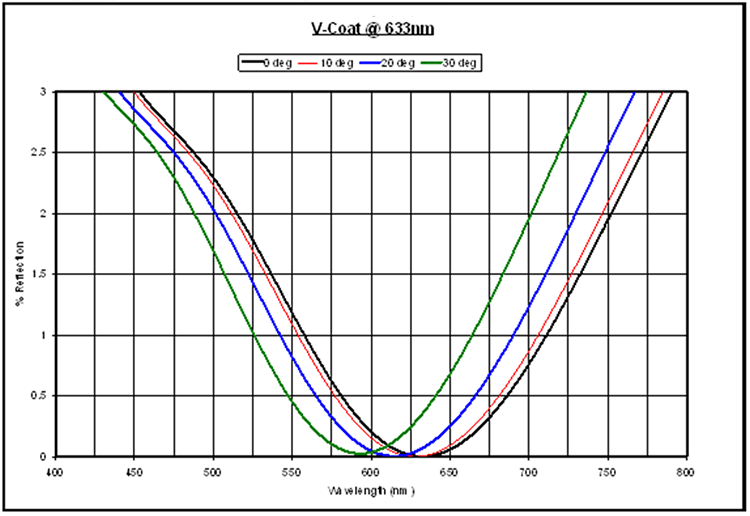

V-Coat AR’s

- The best performance at a single wavelength

- R < 0.2%, AOI: 0-20˚

- Can be optimized for any wavelength