At Optimax we are ―

Manufacturing the future

every day.

We manufacture optics and solutions for your most critical projects using the latest technology and engineering.

The Optimax Story

Since 1991 we have been pushing the boundaries of innovation and technology, solving challenges in the optics industry. That quest has allowed us to be part of some of the greatest technological developments. It benefits mankind not just in the products they use every day but also in the ones they will use in the future.

STARRIS

Optimax has officially launched Starris: Optimax Space Systems! The commercialization of space and the demand for earth-orbit missions are creating unprecedented opportunities in the new space race. Powered by Optimax's 30-year legacy, Starris will lift precision optical payloads from idea to orbit in one year — integrating optics, sensors, and electronics into a modular, pre-tested design that enables customers to enter the booming space economy quickly with low risk.

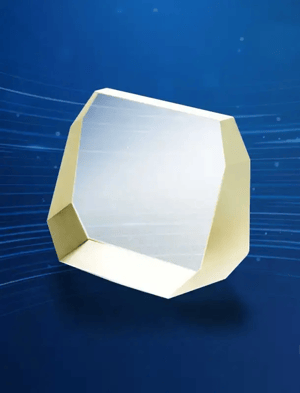

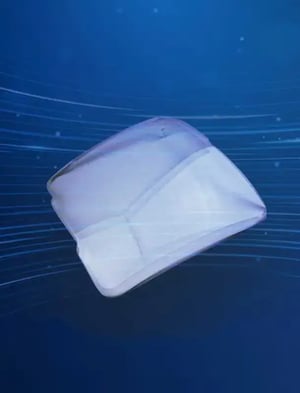

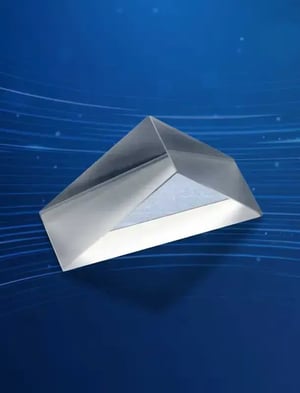

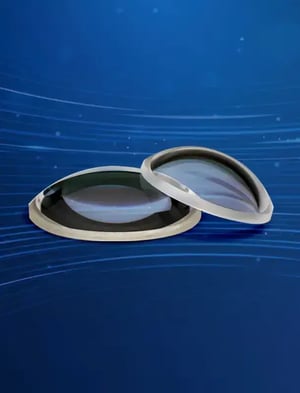

Precision Optics Fast & Accurate

Optimax is a world-class manufacturer of precision optics. Our capabilities incorporate a wide range of manufacturing technologies from which we can engineer solutions that best fit your requirements. Fabrication capabilities range from conventional machinery to highly deterministic CNC machining.

Visit Our Knowledge Center

Explore the Optimax Knowledge Center for access to technical papers, charts, tools, and videos designed to support your optical manufacturing needs.Spilman Leading Optimax into Next Frontier

Starris: Optimax Space Systems Partners with LLNL to Revolutionize Space Telescope Technology

Optimax names new CEO and president