Prototype Optics

Breakthrough optical technologies require an agile approach to prototyping, production, and delivery. Optimax is known for pioneering rapid production of high-quality prototype optics with quick turnaround times. During the 1990s, we were known as the “FedEx of Optics” and we aim to preserve that spirit today, applying our highly robust processes to the complex optical systems of today.

What is Rapid Optical Prototyping?

Prototype optics stem from the drive to generate one-of-a-kind optics. Small-volume production of high-quality prototypes was the logical next step, with contracting product life cycles requiring quicker development processes. Today’s prototyping landscape is more complex, with a wider variety of materials, geometries, and design requirements. Additionally, optical engineers are increasingly seeking more advanced optics that push the boundaries of conventional prototyping capabilities.

At Optimax, we’ve earned a reputation for tackling the most demanding optical prototyping challenges, delivering laser-grade optics and R&D solutions for engineers across various industries.

FIND THE OPTIC SPECIFICATIONS RIGHT FOR YOUR NEEDS:

Types of Optics

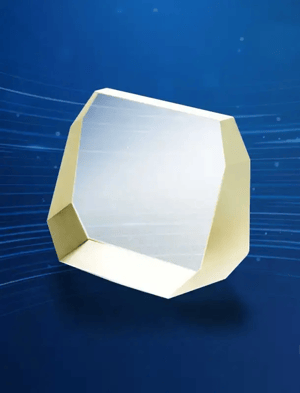

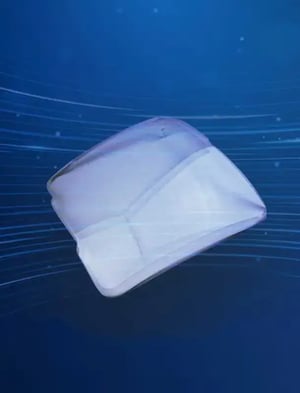

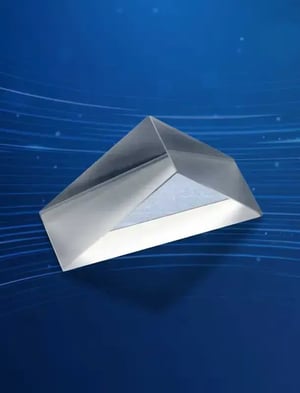

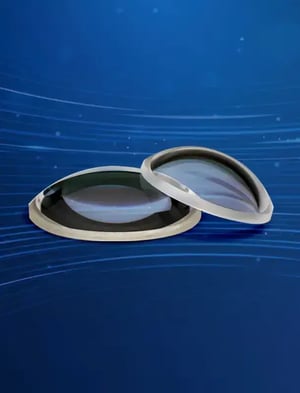

We apply our state-of-the-art optical and mechanical metrology solutions across the full spectrum of our product offerings, including our aspheric optics, cylinders, domes, freeforms, prisms, spheres, and more. Refer to our high-precision optical components for more information.

Manufacturing the Future

At Optimax, we manufacture the future, creating the highest precision optics underlying high-tech systems in key markets and applications. We offer rapid and expedited delivery upon request and are committed to our customers in the long term.

Submit an RFQ to start building your relationship with one of the world’s foremost manufacturers of custom optics.