LGO

We manufacture high-power optics and coatings for demanding high-energy laser applications offering a range of components and coatings available to customize to your program requirements.

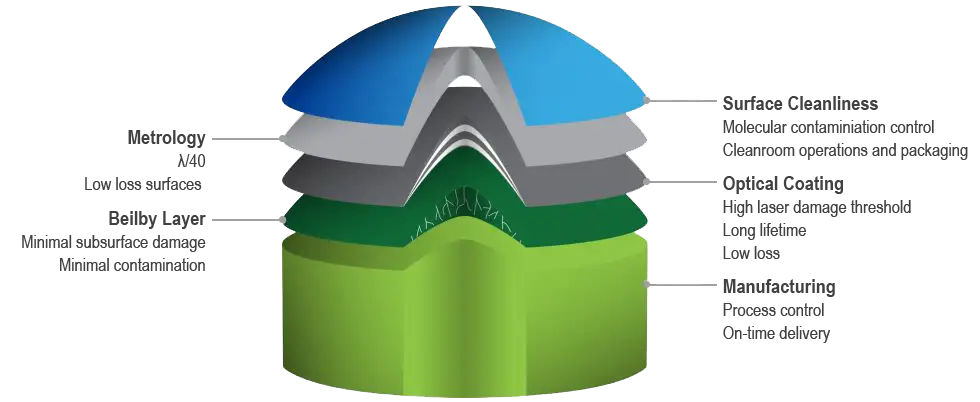

Optimax’s precision sets us apart in the high-power laser optics world with high engineered processes for strictly controlled fabrication, cleaning, coating, and packaging resulting in:

- Low absorption

- High laser damage threshold

- Long lifetime

Laser Grade Optics (LGO)

LGO is an internal business unit at Optimax that was designed to help meet the increasing demands of our customers for the most extreme high precision of components for laser applications. These specialized cells internally are trained and have the technology at hand to manufacture optical components that are:

HIGH PRECISION – LARGE DIAMETER – HIGHLY ENGINEERED

This was an internal transformation from not just a manufacturer but engineered manufacturing that can solve challenging problems for our customers and create solutions to these problems while focusing on specific applications.

FOR THE MOST EXTREME APPLICATIONS – EVERY DETAIL MATTERS.

YOU CAN'T FIND A SOLUTION WITHOUT LOOKING AT THE ENTIRE PICTURE.

Laser Grade Coatings

HIGH LASER DAMAGE – LOW ABSORPTION – LONG LIFETIME

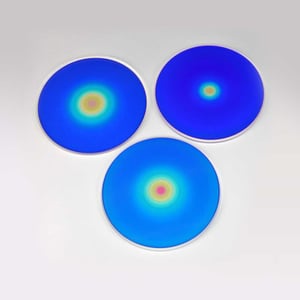

Processes designed specifically for pulsed and CW high-fluence laser applications.

- Proprietary cleaning procedure

- Highly uniform coatings (large diameter steep surfaces)

- OTR coating designed for long lifetime

- No loss of transmission after billions of DUV laser pulses

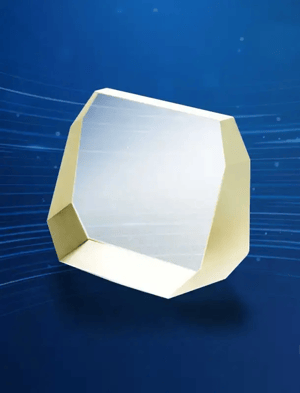

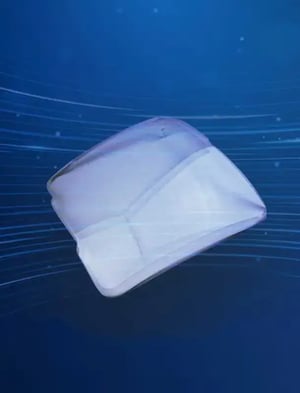

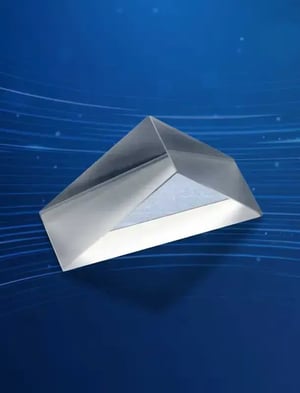

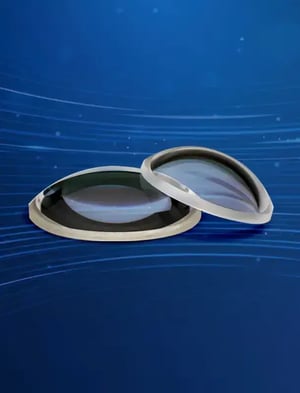

Types of Optics

Optimax is a world-class manufacturer of precision optics. Our capabilities incorporate a wide range of manufacturing technologies from which we can engineer solutions that best fit your requirements. Fabrication capabilities range from conventional machinery to highly deterministic CNC machining.

Solutions

Optimax has developed superior fabrication and coating capabilities for advanced optics designed for use in Directed Energy, Deep Ultraviolet (DUV), and High Power Laser (HPL) systems.

Defense: Directed Energy

Directed energy applications focus laser energy over long ranges for targeted results for defense systems.

Optimax takes ownership of the entire process and is your go-to partner for complete laser-grade optic solutions for defense systems. We back up our performance with third-party verified low absorption and high-laser-induced damage thresholds.

- Large optics up to 500 mm

- Complex geometries

- High-fluence laser coatings

- Advanced in-house metrology, including cavity ring-down

Semiconductor: Deep Ultraviolet (DUV)

Precision optical systems with high throughput and long life for the semiconductor industry. Short wavelength deep ultraviolet lasers for nanoscale linewidth imaging.

- Large optics up to 500 mm

- Complex geometries

- Cleanroom facility

- Proprietary low-loss polishing and coating

- Useful life measured in billions of pulses

- Coating uniformity on steep surfaces

Industrial: High Power Laser (HPL)

High-power laser optics, including systems for large-format industrial material processing and research. Our advanced optics allow uniform transmission across the lens and provide long, useful life in high-fluence applications.

- Large optics up to 500 mm

- Complex geometries

- High CW laser damage thresholds

- Low absorption surfaces and coatings

Manufacturing the Future

At Optimax, we are manufacturing the future, creating the highest precision optics underlying high-tech systems in key markets and applications. We offer rapid and expedited delivery upon request and are committed to our customers in the long term.

Submit an RFQ to start building your relationship with one of the world’s foremost manufacturers of custom optics.