We are a world leader in high precision optical manufacturing, delivering custom optics to a wide range of innovators around the globe. Meeting these goals demands the right people. Teamwork, adaptability, and an enthusiastic approach to problem-solving are central to the Optimax culture. But what unites all our employees best is a hunger to continuously learn. We strive to find driven individuals who are committed to lifelong learning; who will continue to add value in their work throughout long and successful careers.

Ordering Process

At Optimax, we manufacture high-precision optics for a range of applications, providing a superior customer service experience. We are committed to building the future by cultivating critical partnerships with optical engineers and key decision-makers across the full spectrum of optical engineering and design. If you would like to talk through the ordering process, contact a member of the Optimax team directly.

Inspection Data Options

We perform 100% inspection of manufactured optical components for all orders. Data packets can be provided electronically with three options available, each of which is outlined below. When placing an order, please give some consideration to which option works best for your project.

Complying with manufacturing standards issued by:

Customer defined test plan or

A la Carte inspection options available include:

Packaging Options

Optimax cleans and wraps each optic to protect it from mechanical and chemical (staining) damage and desiccant will be added when necessary to protect the lenses from staining. The optics are then wrapped and packed into a protective shipping box.

If interested, you may select non-contact or clean-room packaging.

Standard: Cotton Bag

Standard: Lens Paper/Bubble Wrap

* For optics smaller than 15mm in diameter, gel capsules are available upon request.

Non Contact: PETG

*Additional cost

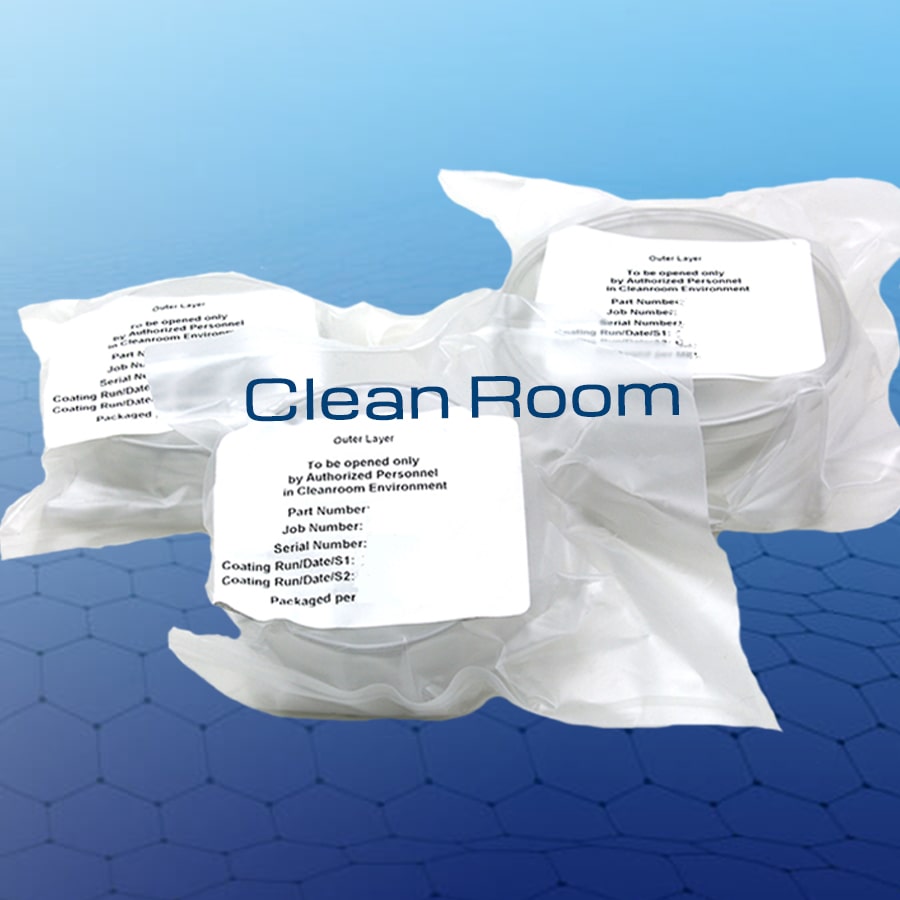

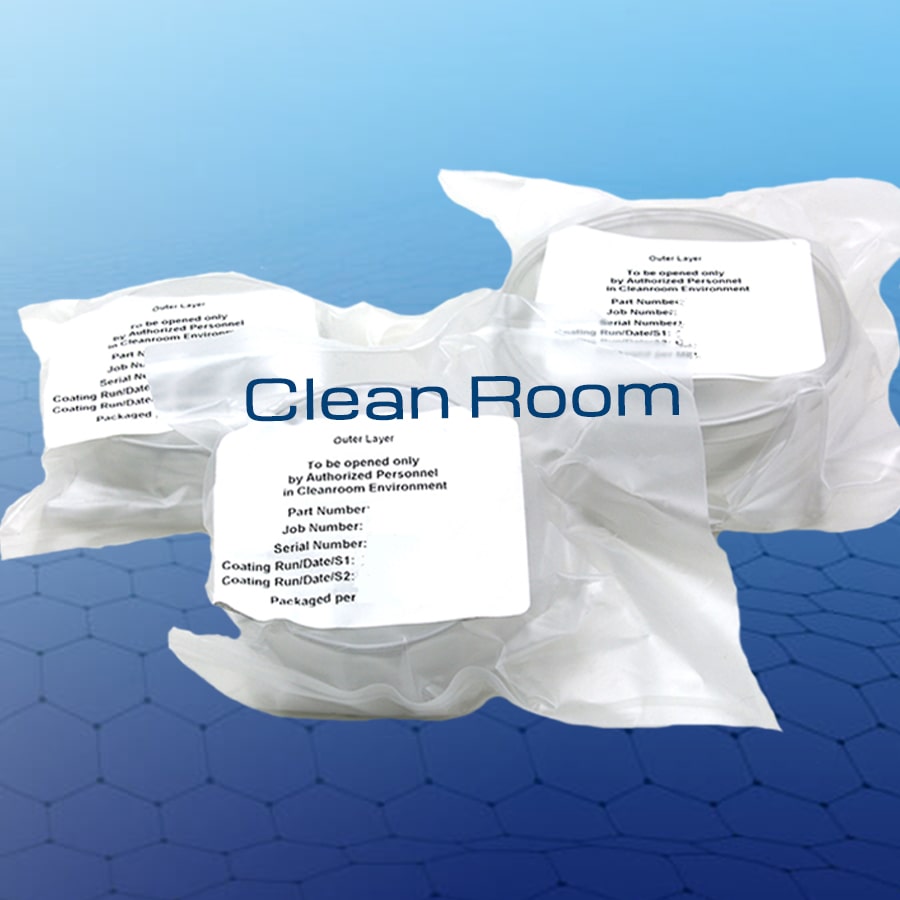

Clean Room

*Additional cost

Corporate & Compliance Information

Optimax operates under our Business Terms and Conditions and Vendor Terms and Conditions. To make sure you receive the appropriate documentation, please review the terms and conditions listed below as well as the other documents in our library that can be useful for the ordering process.

Expedited Delivery

If expedited delivery is requested at the time of order, our team will assess our ability to meet the delivery. This includes verifying the availability of optical materials, workforce availability, and technical requirements.

Optimax provides an On-Time Guarantee. We work hard, but we’re not perfect, so any unearned premium will be refunded to the customer in the event of late delivery.