We are a world leader in high precision optical manufacturing, delivering custom optics to a wide range of innovators around the globe. Meeting these goals demands the right people. Teamwork, adaptability, and an enthusiastic approach to problem-solving are central to the Optimax culture. But what unites all our employees best is a hunger to continuously learn. We strive to find driven individuals who are committed to lifelong learning; who will continue to add value in their work throughout long and successful careers.

REQUEST A QUOTE

Our quotes are structured to offer standard pricing and delivery – quicker delivery options are available upon request.

LEARN FROM THE EXPERTS

Discover how Optimax is changing the future of optics, and view our extensive library of resources.

JOIN OUR TEAM

We are looking for individuals that are committed to lifelong learning and creating value through their hard work.

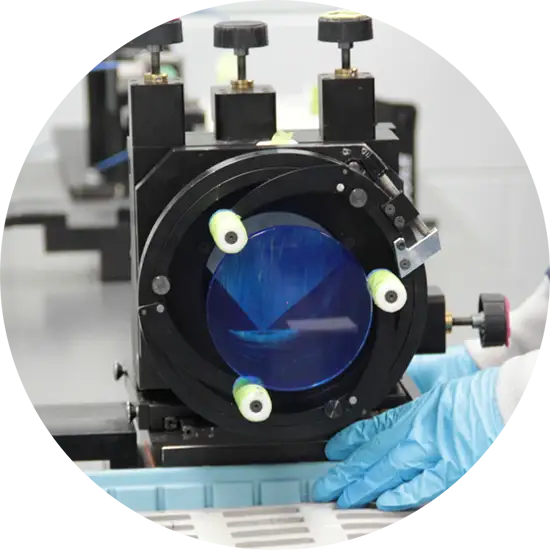

Why is Optical Metrology important?

Optical metrology is the study of measurement using light. It is often preferable to mechanical metrology due to its greater accuracy, versatility, and ability to profile delicate workpieces. An optician’s ability to finish an optical surface is often limited by metrology. Measuring the specific attributes of a lens to known certainties establishes lens quality, which creates value for the customer. Reliable inspection data, therefore, removes unknowns in optical system modeling and performance. At Optimax, we run a continuous improvement program for quality assurance to identify measurement uncertainties and minimize their impact upon optics inspection.

Art of Aspheres

Aspheres have one or more optical surfaces of non-constant curvature.

Manufacturing and metrology of complex aspheres is an emerging science for optical fabricators: Optimax leads the way in our investment in cutting-edge equipment and testing, research and training, and track record of performance on customer programs.

Learn more about our asphere metrology capabilities in our brochure.

Technology

Our approach to optical precision focuses on continual innovation and using the most specialized tools available. We have a suite of industrial metrology solutions to meet the most extreme measurement needs. These include: precision standard fizeau interferometers for irregularity measurements in spherical and plano surfaces; surface profilers for non-spherical surfaces (i.e. aspheres), and stitching interferometers to measure multiple zones on a lens surface, then mathematically stitch the data together to determine irregularity over the full aperture.

The new Optimax Metrology Laboratory provides the best possible environment for precision optical measurements. With extreme vibration isolation and temperature control, the facility is intended for measuring high-precision optical components to accuracies better than 50th wave. Additionally, specialized software tools that measure irregularity for comparison to a Zernike fit specification are available to optical designers for measurement analysis.

Technical Expertise

Do you want to learn more about our optical manufacturing innovation? Refer to our Knowledge Center to read technical papers on, aspheres, business leadership, coatings, freeform optics, innovative optics manufacturing, and lens tolerancing & inspection.

Manufacturing the Future

At Optimax, we are manufacturing the future, creating the highest precision optics underlying high-tech systems in key markets and applications. We offer rapid and expedited delivery upon request and are committed to our customers in the long term.

Submit an RFQ to start building your relationship with one of the world’s foremost manufacturers of custom optics.