We are a world leader in high precision optical manufacturing, delivering custom optics to a wide range of innovators around the globe. Meeting these goals demands the right people. Teamwork, adaptability, and an enthusiastic approach to problem-solving are central to the Optimax culture. But what unites all our employees best is a hunger to continuously learn. We strive to find driven individuals who are committed to lifelong learning; who will continue to add value in their work throughout long and successful careers.

REQUEST A QUOTE

Our quotes are structured to offer standard pricing and delivery – quicker delivery options are available upon request.

LEARN FROM THE EXPERTS

Discover how Optimax is changing the future of optics, and view our extensive library of resources.

JOIN OUR TEAM

We are looking for individuals that are committed to lifelong learning and creating value through their hard work.

What are Optical Domes?

An optical dome is composed of two parallel optical surfaces. Optical domes are unique because, unlike any other optical components, the key attribute of the dome is to have no optical effect. Mirrors reflect light, lenses bend light, and domes ideally change nothing.

Typically the lead element in an optical system, a dome is often exposed to the environment and protects electronic sensors. Accordingly, domes made from hard ceramic materials are preferred due to their ability to withstand wind and rain erosion. Domes are typically found in single-use defense applications and submersible vehicles for deep ocean exploration.

Specifying Parallel Optical Surfaces

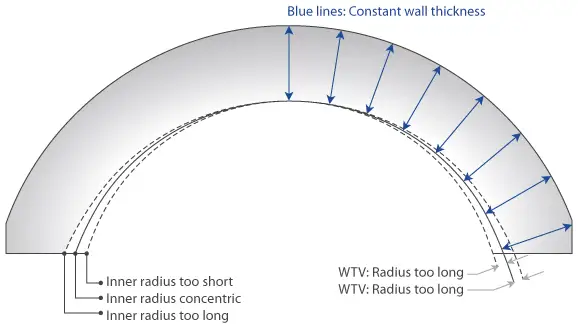

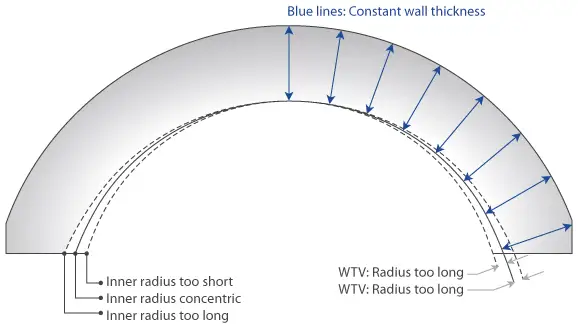

Specifying an optical dome demands definitions for the material, one radius, center thickness, and wall thickness variation – sometimes abbreviated to WTV. Other qualities tend to follow the specifications of standard spherical lenses.

The materials used to fabricate parallel optical surfaces are determined by application; primarily the operating conditions and the required transmission. Thus, optical domes are sometimes classified by wavelength (i.e. infrared optical domes), and other times by their composition (i.e. zinc selenide domes). At Optimax, we fabricate optical domes suitable for applications spanning a broad spectral range, from UV through to IR applications. We also routinely grind and polish premium optical materials like aluminum oxynitride, cerium alumina, magnesium aluminate, and zinc selenide.

The material, one radius, center thickness, and wall thickness variation (WTV)

Image above: Description of a Dome, WTV related to radius error, grossly exaggerated for illustrative purposes.

Manufacturing Optical Domes

Optical domes are hemispheric systems composed of two parallel optical surfaces. With no discernible optical effects, domes present a clear field of view between two environments, hence they are often used as the lead element in precision optical assemblies. Optimax manufactures optical domes to tight tolerances using deterministic CNC machining, providing reliable results for most optical materials, including glass, fused silica, ALON™, CeraLumina™, Spinel, and ZnS.

Unlike mirrors and lenses, optical domes do not alter the light passing through them, which is ideal for critical applications such as single-use defense and navigation systems for submersible vehicles.

FIND THE OPTIC SPECIFICATIONS RIGHT FOR YOUR NEEDS:

Manufacturing Tolerance Chart KNOWLEDGE CENTER Coating UniformityTechnical Expertise

Do you want to learn more about our optical manufacturing innovation? Refer to our Knowledge Center to read technical papers on, aspheres, business leadership, coatings, freeform optics, innovative optics manufacturing, and lens tolerancing & inspection.

Manufacturing the Future

At Optimax, we are manufacturing the future, creating the highest precision optics underlying high-tech systems in key markets and applications. We offer rapid and expedited delivery upon request and are committed to our customers in the long term.

Submit an RFQ to start building your relationship with one of the world’s foremost manufacturers of custom optics.